Pellet & Multi Fuel Vent System

Chimney

Chimney Supervent

Venting

Venting Metal

PelletVent Pro For Biofuels

Usage:

PelletVent Pro is a venting system designed for stoves and inserts that use wood pellets and oil fuel. It is also built to vent biofuel products such as corn, switch grass, cherry pits, soybeans, coffee husks, sunflower hulls, walnut shells and wheat, to name a few. (Rated for continuous use flue temperatures up to 570° F.)

Features and Benefits:

- Sturdy collars for snug fit.

- Approved with 45 elbow termination and collar with screen.

- 45 Degree, or 90 Degree elbows are crimped for improved air tightness.

- Higher grade Stainless liner for improved resistance to corrosion.

- Collars and joints sealed internally with high temperature sealer.

Sizes:

3” & 4” Diameter

Listing:

Listed to UL 641, ULC S609, and ULC/ORD C441

Materials:

Case - GalvalumeT AZ 150 Liner - Type 304 - Stainless Steel Collar - Aluminized

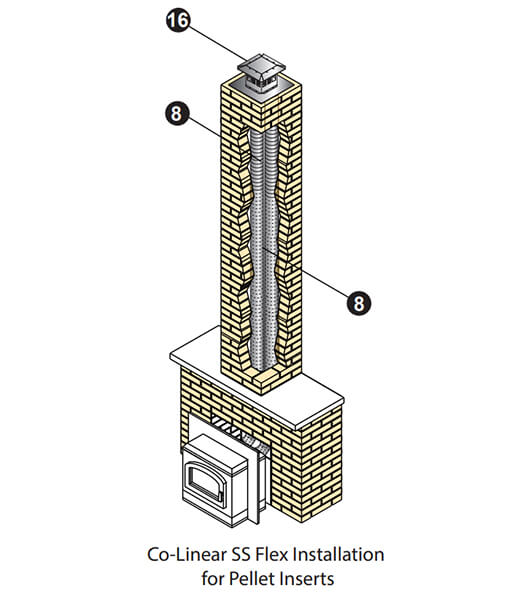

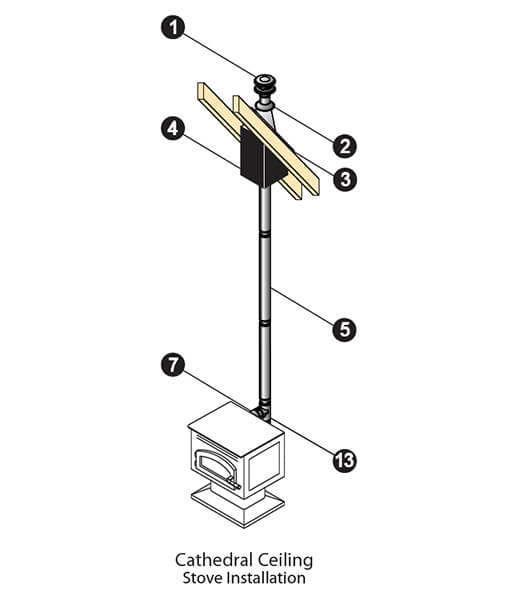

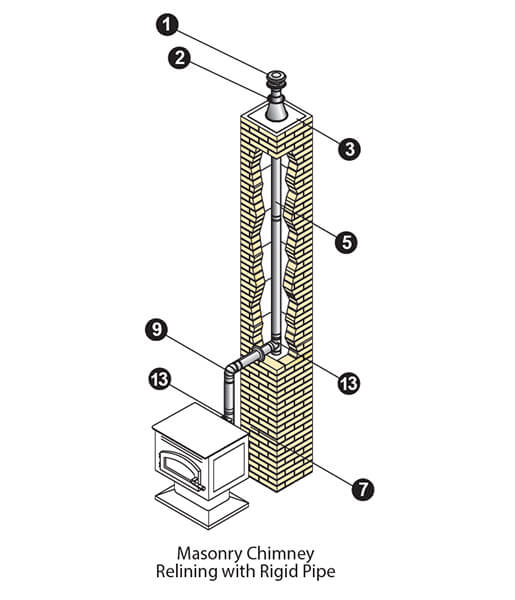

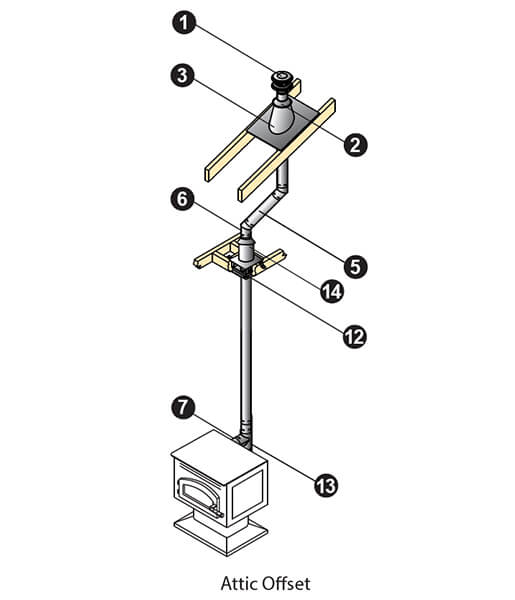

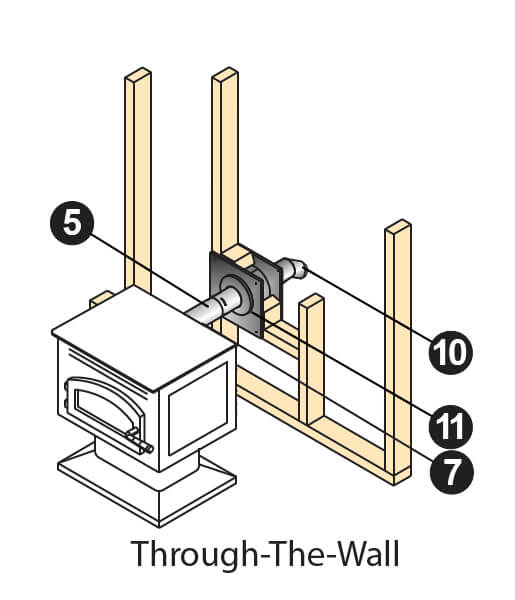

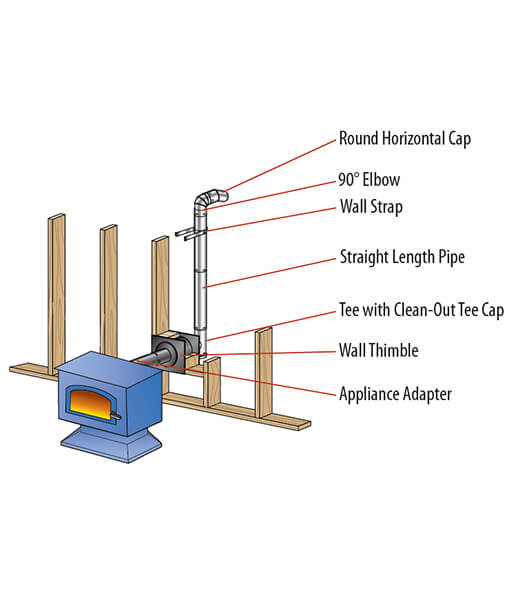

Typical Installations

| 1 | Vertical Cap |

| 2 | Storm Collar |

| 3 | Flashing |

| 4 | Cathedral Ceiling Support Box |

| 5 | Straight Length Pipe |

| 6 | 45° Elbow |

| 7 | Appliance Adapter |

| 8 | Flex Length |

| 9 | 90° Elbow |

| 10 | Horizontal Cap with Rigid Pipe |

| 11 | Wall Thimble |

| 12 | Ceiling Support Firestop Spacer |

| 13 | Tee w/ Clean-Out Tee Cap |

| 14 | Wall Strap |

| 15 | Attic Insulation Shield |

| 16 | Prairie Termination Cap |

| 17 | CAS Adjustable Wall Channe |

- Refer to our Typical Venting Installation drawings to select the appropriate component parts for your installation.

- The inner pipe diameter should match the outlet size of the appliance. For installations that require 4” vent and the appliance has a 3” outlet, use an Increaser Adapter 3”-4”.

- Check the appliance manufacturer's installation instructions to confirm which types of vent configurations are permitted (i.e. horizontal, vertical, chimney reline, etc.). Also, check for any venting restrictions such as maximum horizontal run, minimum and maximum vertical rise, maximum offset, etc.

- Be fire safe! Maintain the minimum clearances (air-space) between the vent pipe and nearby combustibles, as specified in the appliance manufacturer's installation instructions. Use proper support and bracing. Follow local building codes and have your venting system inspected.

Planning Your Installation

| 1 | Refer to the Typical PelletVent Pro Installations diagram, on the opposite page, to be familiar with some of the standard PelletVent Pro installations and the required component parts. |

| 2 | For a horizontal termination, you will need a Wall Thimble and a Horizontal Cap. The cap must be installed with a 6" clearance to the outside wall (refer to appliance manufacturer's installation instructions for other clearances). |

| 3 | For a vertical termination, you will need a Cathedral Ceiling Support Box or Flat Ceiling Support, Attic Insulation Shield (if passing through an attic), Flashing, Storm Collar, and Vertical Cap. |

| 4 | Determine the length of PelletVent Pro pipe required. For a vertical termination, measure the pitch of the roof and select the proper flashing. The required minimum height above the roof is 12". |

| 5 | Pellet stove inserts in masonry fireplaces will require a flex pipe to snake the vent past the smoke shelf. For transition from PelletVent Pro to an existing DuraPlus, DuraPlus HTC, or DuraTech Chimney, a Chimney Adapter is available. |

| 6 | For vertical rise of PelletVent Pro on the outside of the house, Wall Straps should be used at 4' intervals to provide proper support. |

| 7 | Important! Check to be sure that the appliance and the venting system are in compliance with all minimum clearance to combustible requirements. |

WARNING

WARNING

Failure to follow the installation instructions could cause FIRE, CARBON MONOXIDE POISONING, OR DEATH. If you are unsure of installation requirements, call the phone number listed on the instructions, 800-835-4429 or visit www.duravent.com.

Dimensions & Specifications

- PelletVent Pro Catalog(pdf - 6.60 MB)

- DuraVent Installation Instructions(pdf - 1.90 MB)

CLEARANCES AND APPLICATIONS

DuraVent's PelletVent Pro is listed by Underwriters Laboratories as vent for listed appliances that burn oil, pellet, corn, and other biofuels. PelletVent Pro is also listed as a masonry reliner with the minimum clearance 0" from vent to masonry, and 0" clearance from the masonry to nearby combustibles. Never fill any required clearance space with insulation or any other materials (except insulation explicitly approved by DuraVent as noted below). Combustible materials include (but are not limited to) lumber, plywood, sheetrock, plaster and lath, furniture, curtains, electrical wiring, and building insulation except that noted below.

In the United States and Canada the minimum clearance to combustibles from PelletVent Pro is 1" for oil, pellet, corn or other biofuel applications.